Primary Gas Coolers (PGC) are experiencing severe degree of corrosion as these are getting exposed to ammonia vapors, hot humid steam and other chemicals of the process plant. High condensation rates at this torrid zone has been accelerating the rate of corrosion much faster.

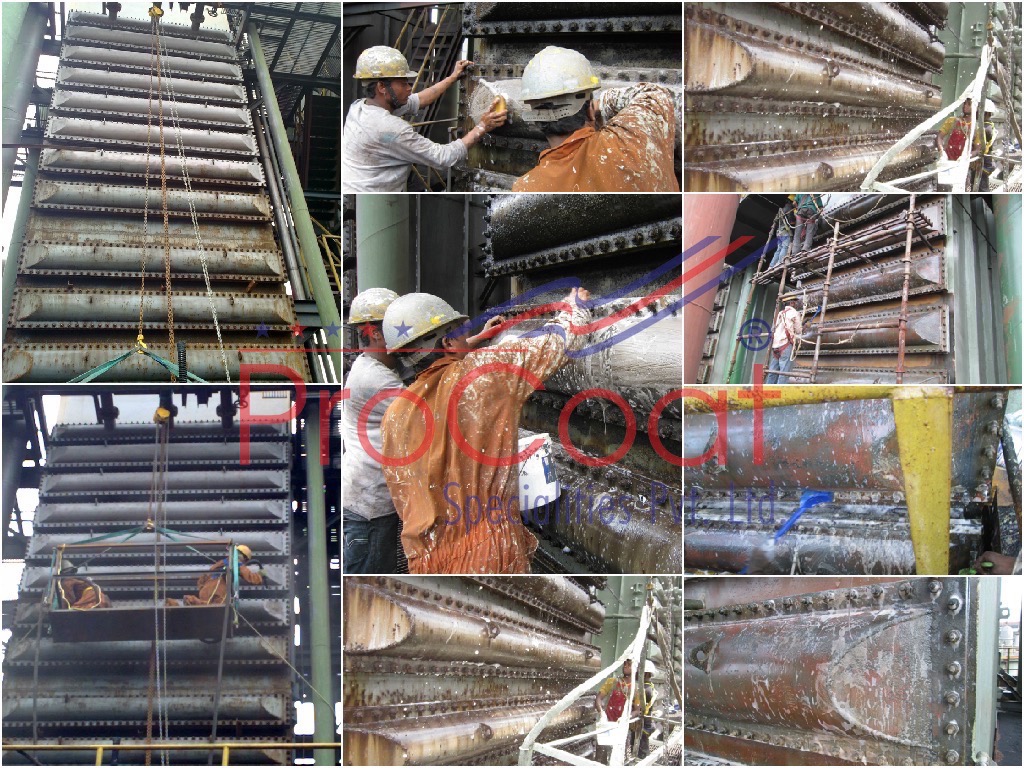

These PGC’s stand tall about 30 meters above ground level. In order to access all the parts of this equipment surface, ProCoat team has carried out the surface preparation and application works with the help of hanging platform administered by safe working methods. Initially the surface was detergent cleaned and water washed thoroughly to eliminate the adsorbed chemicals from the surface, making the surface free from external contaminations.

Over the dry contamination free surface, copper slag abrasive blast cleaning method was implemented to attain the surface roughness essential for coating application making sure the surface profile is to an average of 75+ microns with Sa 2.5 surface finish.

Portion by portion of this gigantic structure was coated using ProCoat chemical and abrasion resistant coating system, to the desired thickness levels as per the requirements.

Inherent quality checks all along the surface neutralization, surface preparation & execution of coating application works have been incorporated to establish the sustainable performance of coating for longer durations of time.