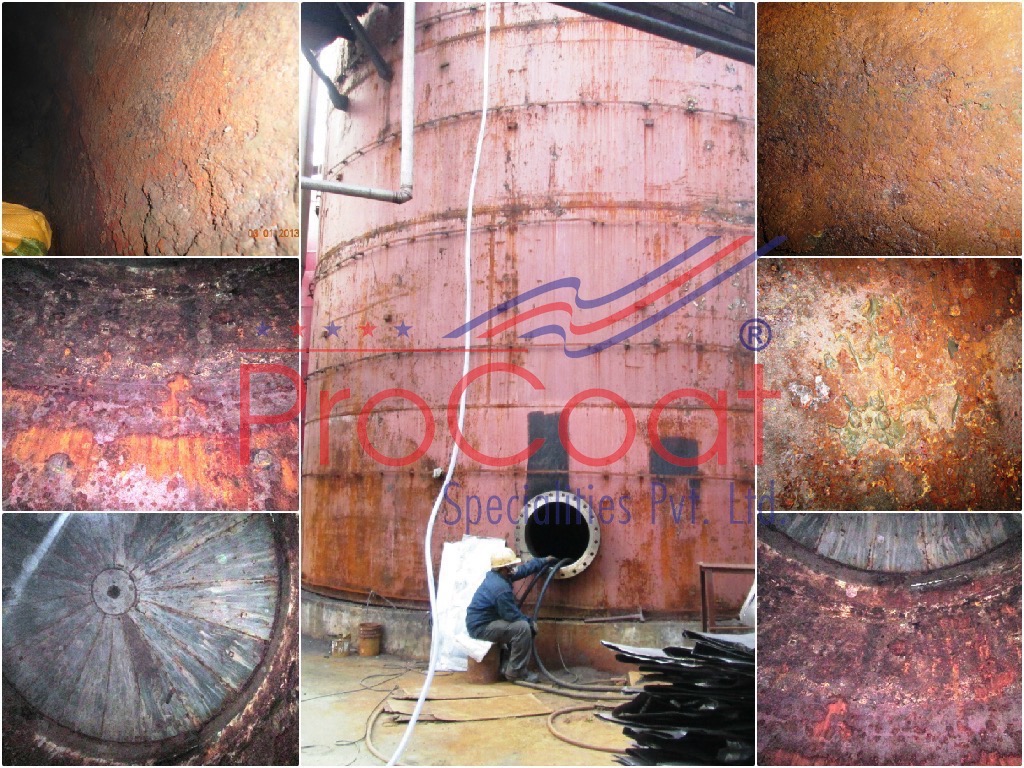

Internal surface of this Sulphur Solution Storage Tank is constantly in contact with the medium and the dome of the tank having continuous contact of the vapours generated inside the tank. On a account of such operating conditions prevailed inside the tank, the surface internally has been corroded very severely which lead to loss of metal and reduction in shell thickness of the tank. Looking at the desired needs of protection, ProCoat Coatings were the best choice that deemed fit for this application.

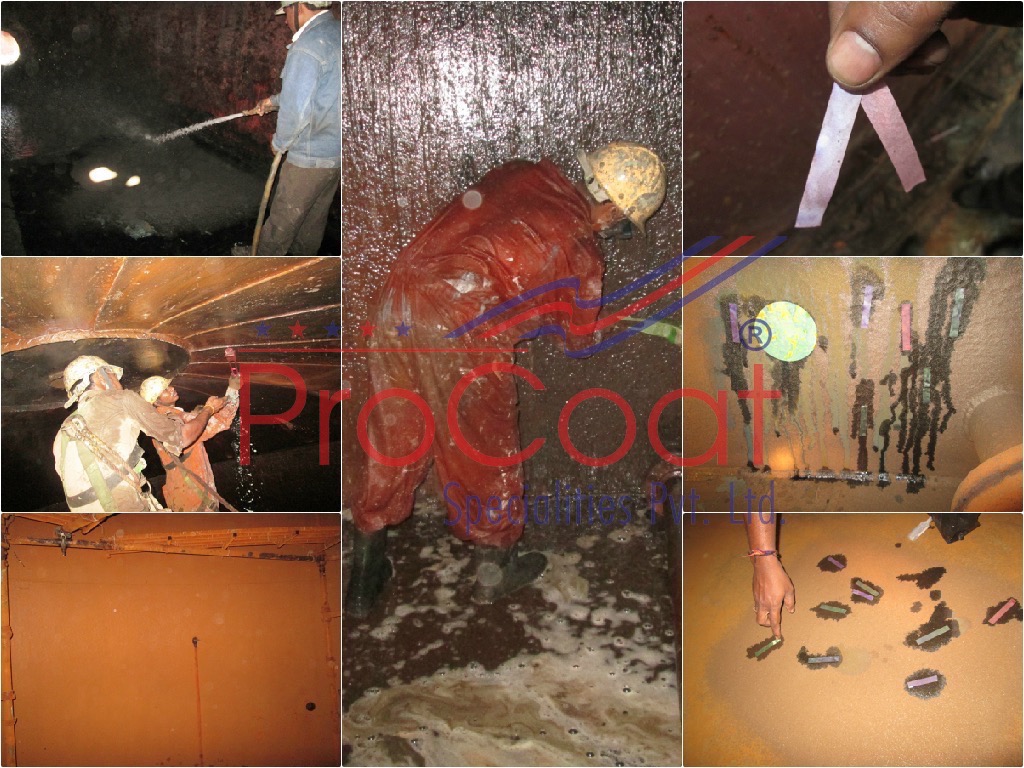

Initially the surface was neutralized by means of water washing and detergent cleaned, scrubbing the surface to eliminate the deposited traces of corrosion causing elements. After the completion of this task relevant test methods were carried out over the surface to checks for the presence of chemical and corrosion causing agents over the surface.

The surface was blast cleaned once & water washed again to remove further remaining traces of chemical content which was cross-checked using relevant test methods. Second round of blast cleaning was carried out using copper slag abrasive media to Sa 2.5 surface profile to near white metal finish ensuring the necessary surface roughness.

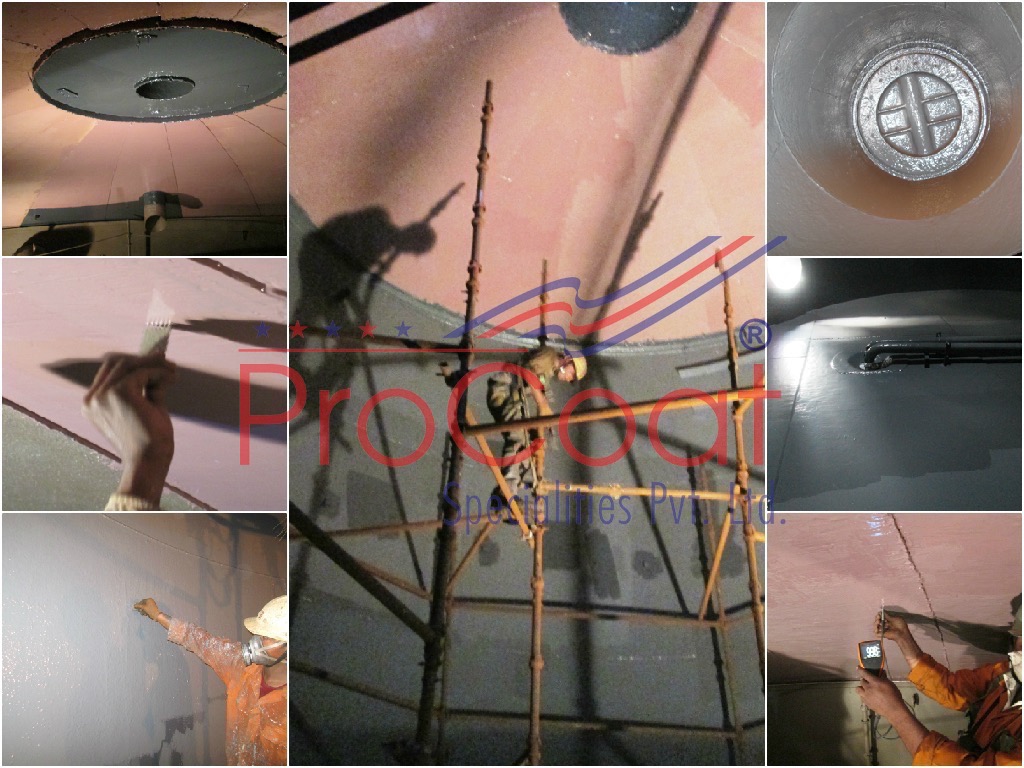

Over the prepared surface, ProCoat coating was applied using spatulas & synthetic rollers in order to deposit the material all over the surface uniformly. Two different coatings systems were incorporated for this application, an high end ProCoat Coating system was applied to the tank bottom surface which not only provides resistance to corrosion but also the endurance to the acting load of the liquid which is being stored inside the tank. Rest of the tank internal surface was coated using ProCoat’s chemical resistant coating system to offer the best protection the metal surface from falling prey to the working corrosive medium.

Quality measurement checks in terms of the coating thickness being deposited over the surface was done using the Elcometer WFT Comb. Once the coating was cured, Dry Film Thickness was measured using the Elcometer DFT Gauge & examined with Holiday Spark Tester to ensure firm coating integrity. To execute the entire task qualitatively inside this 11 meter tall tank, abiding to the safe applications methods, a tailor made scaffolding system was installed to access all parts of the tank surface which has been coated with ProCoat Advanced Polymer Coating System to establish the righteous protection to the metal surface.