ProCoat – 9111

High Performance Advanced Low Viscosity Polymer Primer For Sealing And To Hold Blast Finish Until A Coating System Is Applied

Product Profile

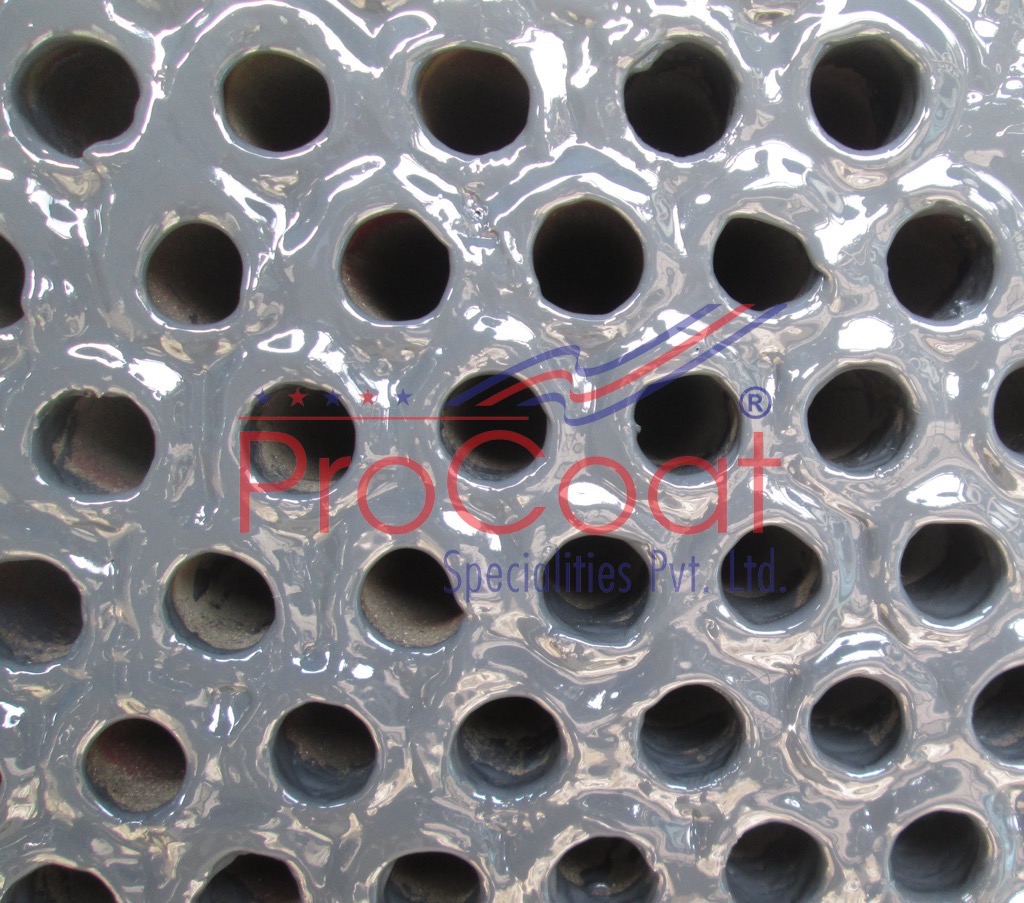

ProCoat – 9111 is solvent free, 100% solids, low viscosity polymer primer with amine curing system, designed as a penetrating pre-primer. It is ideally suited for use on large metal surface areas that hold the blast until a ProCoat coating system is applied. ProCoat – 9111 increases adhesion of a coating system to metal surface which cannot be blast cleaned to SA2.5 finish. Its excellent chemistry enables it to penetrate through the micro pores of rusty surface and cures to a tough, water resistant coating. ProCoat – 9111 is ideal as a sealer on aged “white rusted” zinc surfaces and aged pitted steel prior to application of corrosion protection coating system. ProCoat – 9111 is a choice as a primer for concrete surfaces especially if hydrostatic pressure can be a problem. A thin film of 40 to 50 microns can be applied by a roller or short bristle brush.

Unique Features

- 100% solids

- No volatile organic compounds

- Nil Shrinkage

- Very low viscosity

- Penetrates rust

- Seals concrete pores

- Primer to concrete if hydrostatic pressure problems

Recommended Few Applications

- Structural Steel Work

- Transmission Towers

- Jetty Structures

- Drinking / Raw Water Tanks

- Waste Water & Sewage Tanks

- Petrochemical Tanks

- Sewer Pipes

- Blast Cleaned Pipelines Prior to Coating

- Concrete Tanks

- Concrete Surface As Primer

- Porous Concrete Surfaces

- Floors